Executive Summary

Hanwha Aerospace has established itself as a formidable force in the global aerospace and defense sector, with 2025 marking record financial performance and strategic expansion across international markets.

The company reported consolidated sales of KRW 6.49 trillion in Q3 2025, representing a 147% year-over-year increase, while operating profit surged 79% to KRW 856.4 billion.

South Korea’s only indigenous aircraft engine manufacturer is transitioning from a regional player to a global competitor, securing multi-billion-dollar defense contracts across Europe, the Middle East, and Asia-Pacific while advancing critical aerospace programs including the KF-21 fighter jet and Nuri space launch vehicle.

With projected 2025 revenues between KRW 11.5 trillion and KRW 12.2 trillion, Hanwha Aerospace is capitalizing on unprecedented global defense spending and the accelerating shift toward allied defense cooperation.

Also Read:

Table of Contents

Key Facts: Company Profile and Business Overview

Company Name: Hanwha Aerospace Co., Ltd.

Founded: 1977 (as Samsung Precision Industry)

Headquarters: Changwon, South Korea

Parent Company: Hanwha Group

Market Cap: Approximately KRW 23+ trillion (January 2026)

Employees: 10,000+ globally

Stock Symbol: 012450.KS (Korea Exchange)

Core Business Segments:

├─ Space: Launch vehicles, satellite systems, rocket engines

├─ Aviation: Aircraft engines, MRO services, engine components

├─ Land Systems: Artillery, armored vehicles, missile systems

├─ Marine: Electric propulsion, smart ship solutions

└─ Defense: Air defense systems, precision munitions

Hanwha Aerospace operates as South Korea’s premier aerospace and defense manufacturer, serving both domestic military requirements and international commercial markets.

The company merged with Hanwha Defense in 2022 to create comprehensive defense capabilities spanning air, land, and space domains.

Image source: hanwha.com

Revenue Growth and Financial Performance

Record-Breaking 2025 Results

The financial trajectory of Hanwha Aerospace demonstrates exceptional momentum driven by defense export contracts and space program achievements.

Q3 2025 results revealed the company’s strongest quarterly performance to date, with consolidated sales reaching KRW 6.49 trillion, representing a 147% year-over-year increase.

Operating profit climbed 79% to KRW 856.4 billion, yielding an operating margin of 13.2%.

Net income attributable to shareholders reached KRW 486.5 billion, up 53% compared to Q3 2024.

Financial Metric | Q3 2025 | Q3 2024 | YoY Change |

|---|---|---|---|

Revenue | KRW 6.49T | KRW 2.63T | +147% |

Operating Profit | KRW 856.4B | KRW 477.1B | +79% |

Operating Margin | 13.2% | 18.1% | -4.9%p |

Net Income | KRW 486.5B | KRW 318.4B | +53% |

Source: Hanwha Aerospace Q3 2025 Earnings Report

Full-Year Projections and Growth Drivers

Industry analysts project 2025 consolidated revenues of KRW 27.2 trillion, representing a 142% year-over-year increase.

EBIT is expected to reach KRW 4.2 trillion, up 106% compared to 2024.

The 2026 consensus estimates call for sales of KRW 31.5 trillion, reflecting a 22.5% annual growth rate, with EBIT of KRW 4.4 trillion.

These projections are underpinned by several key revenue drivers.

Defense export contracts, particularly from Poland, Romania, Egypt, and Estonia, constitute the largest growth catalyst, with multi-year delivery schedules extending through 2030.

The mass production of KF-21 fighter engines, beginning in 2026, creates a substantial domestic revenue stream.

Space launch vehicle operations are transitioning from government-funded development to commercial applications, with planned annual Nuri launches through 2027.

Aircraft engine MRO services continue expanding through partnerships with GE Aerospace, Rolls-Royce, and Pratt & Whitney.

The marine propulsion segment benefits from South Korea’s submarine modernization programs and emerging hydrogen fuel cell applications.

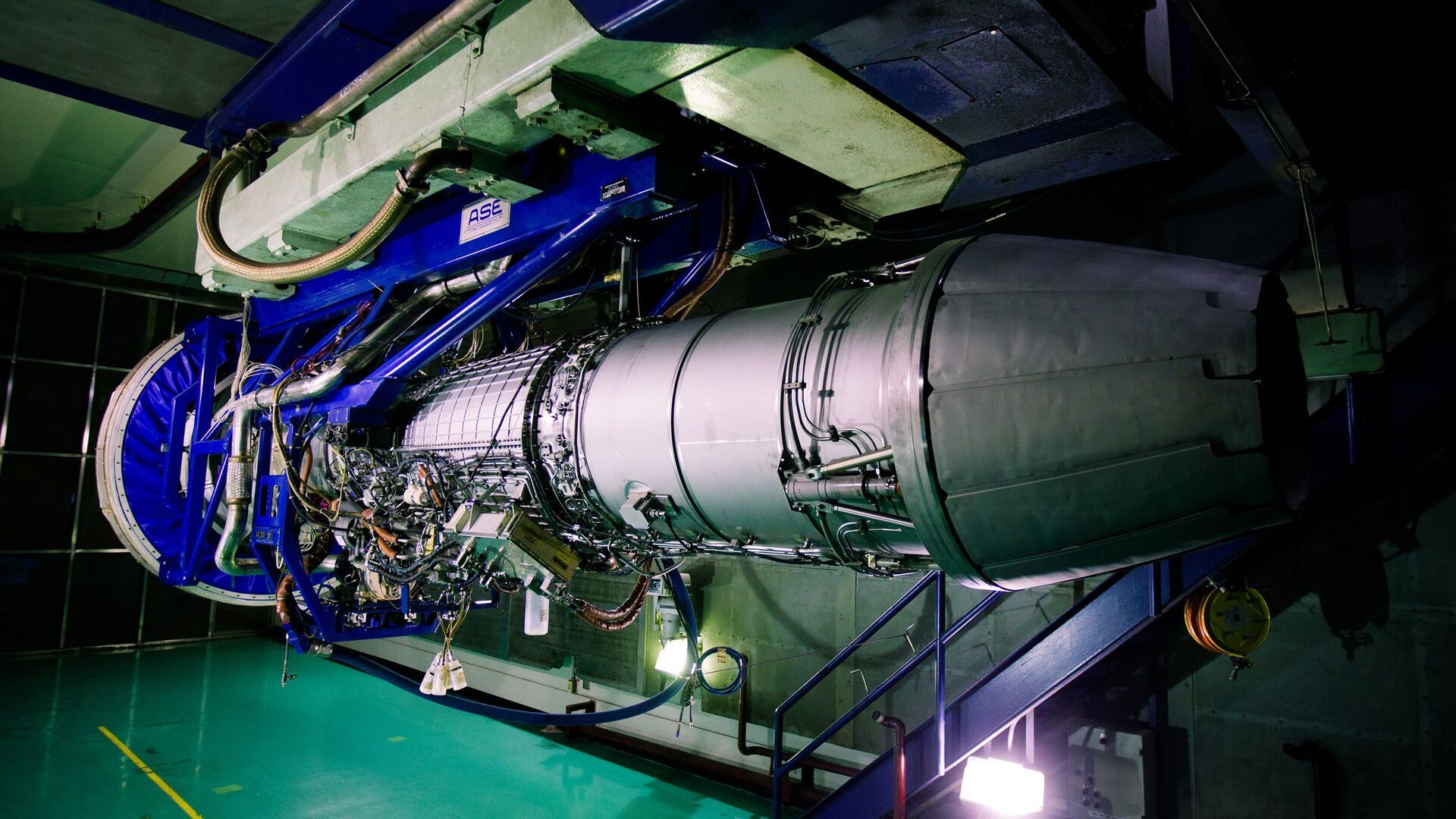

Indigenous Fighter Engine Program Reaches Milestone

KF-21 Boramae Engine Development

December 2025 marked a watershed moment when South Korea announced a KRW 4.1 trillion ($3.4 billion) commitment to develop a fully indigenous fighter jet engine.

This program represents South Korea’s ambition to achieve complete self-reliance in advanced military aviation technology.

Hanwha Aerospace leads the consortium tasked with developing a 15,000-pound thrust-class turbojet engine intended to power the KF-21 Boramae Block 3 variant from the mid-2030s.

The current Block 1 and Block 2 KF-21 aircraft utilize the GE F414 engine, which Hanwha produces under license at its Changwon facilities.

Image source: wikipedia.org

First Mass Production Order

In June 2024, Hanwha Aerospace secured a USD 401 million contract from South Korea’s Defense Acquisition Program Administration to supply 80 F404-102 engines for the initial production batch of 40 KF-21 aircraft.

Deliveries commenced in late 2025, with the Republic of Korea Air Force scheduled to receive its first operational KF-21 units in 2026.

The KF-21 program represents a strategic cornerstone for Hanwha Aerospace’s aviation business.

Beyond domestic procurement, export opportunities are emerging as the UAE, Indonesia, and Poland evaluate the aircraft for their air forces.

Unit costs are estimated at $83 million for Block 1 and $112 million for Block 2 variants, positioning the KF-21 as a cost-effective alternative to Western fifth-generation fighters while offering capabilities superior to many fourth-generation platforms.

Engine Technology Capabilities

Hanwha Aerospace has produced over 10,000 military aircraft engines since establishing its aviation business in 1979.

Current production encompasses engines for South Korea’s entire military aviation fleet, including F-15K fighters, KF-21 advanced fighters, T-50 Golden Eagle trainers, and KUH Surion utility helicopters.

The company operates state-of-the-art engine testing facilities in Changwon capable of full-scale turbine engine validation.

Research and development investments focus on high-temperature materials, advanced turbine blade manufacturing, and digital twin simulation technologies essential for next-generation propulsion systems.

Space Launch Vehicle Leadership

Nuri Rocket Technology Transfer

November 2025 witnessed South Korea’s fourth successful Nuri launch, with Hanwha Aerospace assuming primary operational responsibility for the first time.

This mission marked the transition of the KSLV-II program from government-led development to commercial operations.

Hanwha Aerospace received full technology transfer for the Nuri launch vehicle system, becoming the first private South Korean company to possess complete space launch capabilities.

The three-stage Nuri rocket can deliver 1.5-ton payloads to 600-700 km sun-synchronous orbits.

Image source: koreatimes.co.kr

2026-2027 Launch Schedule

Hanwha Aerospace plans one Nuri launch per year in 2026 and 2027, further advancing South Korea’s space launch vehicle technology.

The fifth Nuri mission is scheduled for late 2026, followed by the sixth launch in 2027.

These missions serve dual purposes: demonstrating commercial launch reliability and validating upgraded components for the next-generation KSLV-III vehicle.

Key technological components produced by Hanwha include the 75-ton liquid rocket engine powering the first stage, turbopump assemblies, fuel feed valves, and attitude control systems.

The company manufactures these components at specialized facilities dedicated to rocket propulsion, leveraging expertise developed over 25 years of participation in South Korea’s space programs.

KSLV-III Next-Generation Vehicle

In 2024, the South Korean government selected Hanwha Aerospace as system integrator for the KSLV-III program, which aims to develop a more powerful launch vehicle capable of lunar missions.

The KSLV-III project targets completion by 2032, with the ambitious goal of sending a lunar module to the Moon.

This represents a quantum leap in both technical sophistication and program scale compared to Nuri.

Hanwha will participate in all development stages from initial design through operational launches, working closely with the Korea Aerospace Research Institute (KARI).

The KSLV-III is expected to utilize more powerful engines and advanced staging technologies to achieve the delta-v requirements for trans-lunar injection.

K9 Howitzer Global Market Dominance

European Expansion Accelerates

The K9 Thunder self-propelled howitzer has emerged as Hanwha Aerospace’s flagship export success story, with operations now spanning 10 countries.

2024-2025 witnessed a series of major contract awards solidifying the K9’s position as the world’s most exported modern artillery system.

Romania signed a contract valued at nearly $1 billion for 54 K9 Thunder howitzers and 36 K10 ammunition resupply vehicles in 2024.

This followed Poland’s massive procurement program that includes hundreds of K9 units with delivery extending through 2028.

Image source: Flickr

Estonia added to the European customer base with contracts for both K9 howitzers and Chunmoo rocket systems.

Norway received additional K9 units in September 2025, expanding their initial procurement.

Middle East and Asia-Pacific Contracts

Egypt signed a KRW 2 trillion ($1.4 billion) contract in 2022 for K9 howitzers, with deliveries beginning in 2025 and continuing through 2027.

India finalized a second K9 contract in 2025, supplementing earlier procurements and including technology transfer provisions for local production.

Australia’s evaluation of the K9 for potential procurement continues, with field trials demonstrating compatibility with NATO-standard ammunition and interoperability with allied artillery networks.

Technical Superiority Factors

The K9’s international success stems from multiple competitive advantages.

Rate of fire capabilities reach 6-8 rounds per minute in sustained operations, with burst rates up to 15 rounds in three minutes.

Range exceeds 40 km with rocket-assisted projectiles, providing standoff capabilities against counter-battery threats.

Automated fire control systems reduce crew requirements to three personnel while enabling rapid position changes.

The K9 demonstrated exceptional cold-weather performance in Polish winter trials and desert endurance in Middle Eastern evaluations.

Modular design facilitates customization for different operational environments and customer-specific requirements.

Chunmoo Rocket System Strategic Contracts

Poland Manufacturing Partnership

December 2025 brought Hanwha Aerospace’s most significant Chunmoo announcement: a KRW 5.6 trillion ($4 billion) contract with Poland to establish local production of CGR-080 guided rockets.

This agreement extends the 2022 framework contract and includes construction of a manufacturing facility in Poland capable of producing 10,000 CGR-080 rockets annually.

The Homar-K program, as Poland designates its Chunmoo procurement, reflects Warsaw’s determination to rapidly rebuild artillery capabilities in response to regional security developments.

Local production beginning in 2027 will create hundreds of Polish manufacturing jobs while providing Hanwha with a European production footprint for potential additional customers.

Estonia Procurement

In December 2025, Estonia finalized a $341 million agreement for six K239 Chunmoo launchers and associated munitions.

Estonia’s existing procurement of K9 howitzers creates an integrated Hanwha artillery ecosystem within the Estonian Defense Forces.

The combination of long-range howitzers and precision rocket systems provides Estonia with credible deterrence capabilities despite its limited defense budget.

Chunmoo Technical Capabilities

The K239 Chunmoo multiple rocket launcher system combines three rocket calibers on a single wheeled platform: 130mm, 239mm, and 239mm guided rockets, plus compatibility with Army Tactical Missile System (ATACMS)-class munitions.

Maximum range exceeds 80 km with guided munitions, enabling deep strike capabilities against high-value targets.

GPS/INS guidance provides circular error probable accuracy of less than 50 meters at maximum range.

The Chunmoo was the first system development project led by a defense company in South Korea, demonstrating Hanwha’s capabilities in complex weapon system integration.

Long-Range Air Defense: L-SAM System Production

November 2025 Contract Award

Hanwha Aerospace secured a KRW 705.4 billion ($482 million) contract from South Korea’s Defense Acquisition Program Administration to produce the Long-Range Surface-to-Air Missile (L-SAM) system.

This marks the transition from development to serial production for South Korea’s uppermost air and missile defense layer.

The L-SAM system forms the outer tier of South Korea’s integrated air and missile defense network, designed to intercept ballistic missiles at altitudes exceeding 40 km.

Combined with the medium-range M-SAM (Chungoong) and short-range H-SHORAD systems, L-SAM completes a comprehensive defense architecture.

System Capabilities and Integration

L-SAM employs advanced hit-to-kill interception technology, directly striking incoming ballistic missiles with kinetic energy rather than proximity warheads.

This approach maximizes kill probability against maneuvering reentry vehicles and minimizes collateral damage from failed interceptions.

Hanwha Systems received a separate KRW 357.3 billion contract in October 2025 for L-SAM multifunction radars, which provide long-range surveillance, tracking, and fire control functions.

The radar systems utilize active electronically scanned array (AESA) technology with simultaneous multi-target tracking capabilities.

Integration with South Korea’s broader defense network enables data fusion from multiple sensors, including early warning radars, Aegis destroyers, and intelligence collection platforms.

This networked approach provides layered defense-in-depth against increasingly sophisticated missile threats.

Redback Infantry Fighting Vehicle: Australian Land 400 Program

2023 Contract Award

Hanwha’s Redback next-generation infantry fighting vehicle (IFV) won Australia’s Land 400 Phase 3 competition in 2023, defeating established European competitors.

The program calls for up to 450 IFVs with delivery beginning in 2027 and continuing through the 2030s.

Contract value approaches AUD 7 billion ($4.6 billion), representing one of Australia’s largest defense procurements this decade.

Advanced IFV Technology

The Redback features several technological innovations distinguishing it from legacy IFV designs.

An advanced suspension system provides exceptional off-road mobility across Australia’s diverse terrain, from tropical forests to desert outback.

Modular armor configurations allow protection levels to be adjusted based on threat environment, balancing survivability with strategic transportability.

The turret accommodates various weapon systems, with the Australian configuration featuring a 30mm cannon and anti-tank guided missile launcher.

Crew capacity reaches 11: three crew members plus eight dismounts, matching or exceeding contemporary IFVs.

Automotive performance includes 60+ km/h road speed with operational range exceeding 500 km.

Australian production will occur at facilities in Queensland, creating over 300 local jobs and establishing Hanwha’s manufacturing presence in the Pacific region.

Technology transfer provisions ensure Australia gains IFV production expertise while Hanwha benefits from access to Australian defense research capabilities.

Unmanned Systems Development

Gray Eagle STOL Partnership with General Atomics

October 2025 brought formal agreement between Hanwha Aerospace and General Atomics Aeronautical Systems (GA-ASI) to co-develop the Gray Eagle Short Takeoff and Landing (STOL) unmanned aerial system.

This partnership combines GA-ASI’s proven Gray Eagle airframe with short-field performance enhancements, co-produced in South Korea and the United States.

The Gray Eagle STOL variant, based on GA-ASI’s Mojave demonstrator, can operate from unprepared airstrips and austere locations without requiring conventional runways.

This capability proves critical for distributed operations where runway access may be limited or threatened.

First flight is targeted for 2027, with production facilities established in South Korea for regional customers.

The platform will be offered to South Korean armed forces, U.S. military services, and allied nations seeking runway-independent persistent surveillance and strike capabilities.

Autonomous Ground Vehicles

Hanwha’s Arion-SMET (Autonomous and Robotic Systems for Intelligence Off-road Navigation-Small Multi-purpose Equipment Transport) completed successful testing with the U.S. Marine Corps in Hawaii during 2023.

The unmanned ground vehicle demonstrated autonomous navigation across challenging terrain and load-carrying capacity of 1,000 pounds.

An upgraded Grunt model launched in 2025 features enhanced range and payload capacity, addressing operational feedback from Marine Corps evaluations.

Applications include logistics resupply, casualty evacuation, remote sensor deployment, and munitions transport.

The system’s modular architecture accommodates various mission payloads, from cargo containers to remote weapon stations.

Manned-unmanned teaming (MUM-T) capabilities enable integration with crewed vehicles, allowing human operators to control multiple autonomous systems simultaneously.

This technology aligns with emerging operational concepts emphasizing reduced personnel exposure to direct combat.

European Manufacturing Expansion

Germany Production Facility Plans

Hanwha Aerospace announced intentions to construct a precision missile manufacturing plant in Germany during an industry day event in Berlin in May 2025.

The facility will support European customers requiring local production for security-of-supply considerations.

Eastern Germany emerged as the preferred location, offering skilled workforce availability, transportation infrastructure, and proximity to Central European customers.

Initial production focus will center on artillery ammunition and precision-guided munitions, with potential expansion to other weapon systems based on European demand.

This investment responds to Europe’s recognition that increased defense spending must include domestic production capacity rather than relying entirely on imports.

Hanwha executives indicated the German facility represents the first of potentially multiple European production sites, with other locations under evaluation for different product lines.

Poland Industrial Cooperation

Beyond the Chunmoo rocket factory, Hanwha established technology cooperation with Poland’s Military Institute of Armament Technology (WITU) in September 2025.

This memorandum of understanding covers joint research and development on ammunition technology, including propelling charges, fuses, and precision guidance systems.

Additional Polish partnerships include chassis component production for Krab self-propelled howitzers, awarded to Hanwha in April 2025.

Poland’s ambitious military modernization program creates opportunities for long-term industrial collaboration extending beyond initial equipment deliveries to sustainment and technology co-development.

Civil Aviation Engine Business

Global Supply Chain Partnerships

Hanwha Aerospace maintains strategic relationships with all major commercial aircraft engine manufacturers: GE Aerospace, Rolls-Royce, and Pratt & Whitney.

These partnerships span from component manufacturing to maintenance, repair, and overhaul services.

The company’s 2022 Rolls-Royce Trusted to Deliver Excellence Award recognized exceptional quality and on-time delivery performance.

Hanwha produces precision-machined components for wide-body and narrow-body engine programs, including GE90, GEnx, LEAP, Trent XWB, and PW1000G families.

International Production Footprint

In 2016, Hanwha established a joint venture with Pratt & Whitney in Singapore (PWMS), participating in a revenue sharing program for next-generation engine development.

Vietnam facilities built in 2017 provide cost-competitive component production while expanding manufacturing capacity.

The 2019 acquisition of EDAC Technologies brought advanced U.S. manufacturing capabilities and customer relationships, rebranded as Hanwha Aerospace USA.

This Connecticut-based operation serves as the North American headquarters for civil aviation business, employing over 500 personnel in precision machining and assembly operations.

The distributed production network enables Hanwha to optimize manufacturing locations based on technical complexity, cost structure, and customer proximity considerations.

Competitive Analysis: Defense Industry Positioning

Korean Domestic Competitors

Within South Korea’s defense sector, Hanwha Aerospace faces competition from several established players.

Korea Aerospace Industries (KAI) serves as the prime contractor for the KF-21 fighter program, though Hanwha supplies the engines.

KAI also produces the KUH Surion helicopter and various trainer aircraft, creating some overlap in rotorcraft and fixed-wing aviation.

LIG Nex1 specializes in missile systems and fire control technology, competing in the guided munitions and air defense sectors where Hanwha also operates.

HYUNDAI WIA (now HD Hyundai Infracore) produces armored vehicles and automotive components for military applications.

However, Hanwha’s vertical integration across engines, vehicles, and weapon systems provides competitive advantages in offering integrated solutions.

International Defense Competitors

Market Segment | Primary Competitors | Hanwha Competitive Position |

|---|---|---|

Aircraft Engines | GE Aerospace, Rolls-Royce, Pratt & Whitney, Safran | Licensed production partner transitioning to indigenous development |

Artillery Systems | BAE Systems, Rheinmetall, Nexter, Elbit Systems | Cost-competitive with proven combat performance; strongest export sales |

Rocket Systems | Lockheed Martin, Roketsan, Norinco | Advanced guidance technology at competitive pricing |

Armored Vehicles | BAE Systems, Rheinmetall, General Dynamics | Modern designs with superior mobility; growing market share |

Air Defense | Raytheon, Lockheed Martin, Thales, Rafael | Domestic Korean requirements drive development; export potential increasing |

Analysis: Hanwha’s competitive strength lies in aggressive pricing, rapid development cycles, and willingness to offer technology transfer arrangements that Western competitors increasingly avoid.

Hanwha’s pricing typically runs 20-30% below comparable Western systems while meeting similar performance specifications.

This cost advantage proves decisive in competitions for price-sensitive customers, particularly in Central Europe, Southeast Asia, and the Middle East.

Technology transfer provisions distinguish Hanwha from many Western competitors increasingly reluctant to share intellectual property.

Poland, Romania, and India have secured local production rights that build indigenous capabilities while creating political support for large procurement programs.

Development speed represents another differentiator.

The Chunmoo system progressed from concept to operational deployment in less time than comparable Western programs, demonstrating organizational agility and risk tolerance.

Recent Strategic Developments

January 2026: Autonomous Surface Vessel Partnership

On January 8, 2026, Hanwha announced a formalized partnership with HavocAI to develop 200-foot autonomous surface vessels for U.S. defense forces.

This collaboration combines Hanwha’s shipbuilding capabilities with HavocAI’s autonomy software to create unmanned platforms for maritime patrol, mine countermeasures, and logistics missions.

Following a successful joint technology demonstration in October 2025 from Hanwha Ocean’s Geoje shipyard, the companies committed to full-scale development.

The autonomous vessel program addresses U.S. Navy requirements for distributed maritime operations while expanding Hanwha’s presence in naval systems beyond propulsion components.

December 2025: Indigenous KF-21 Engine Development Investment

The South Korean government’s $3.4 billion commitment to indigenous fighter engine development represents a strategic national priority.

This program will span over a decade, targeting initial operational capability in the mid-2030s.

Beyond the KF-21 Block 3 application, a successful indigenous engine program positions South Korea to compete in the global fighter engine market, currently dominated by a handful of Western companies.

The technical requirements include thrust class comparable to the F414 (approximately 15,000-16,000 pounds), advanced materials for high-temperature turbine sections, and digital engine control systems.

November 2025: Fourth Nuri Launch Success

The November 27, 2025 Nuri launch deployed more than a dozen satellites to orbit, marking Hanwha’s transition to operational launch provider.

Unlike previous Nuri missions led by government researchers, Hanwha assumed primary responsibility for vehicle integration, launch operations, and mission management.

Cube satellites from multiple Korean universities and research institutions comprised the payload, demonstrating Nuri’s commercial viability for small satellite deployment.

The successful mission validated technology upgrades implemented since the third launch and confirmed Hanwha’s readiness for routine space access operations.

Financial and Commercial Implications for Industry Stakeholders

Defense Budget Trends Driving Growth

Global defense spending increases, particularly in Europe and Asia-Pacific, create sustained demand for Hanwha’s product portfolio.

NATO’s commitment to minimum 2% GDP defense spending drives European procurement, with Eastern European nations allocating even higher percentages given regional security concerns.

Poland’s defense budget reached approximately 4% of GDP in 2025, funding massive modernization programs.

South Korea maintains defense spending around 2.8% of GDP, supporting both domestic capability development and export-oriented production.

Middle Eastern nations continue defense investments focused on capabilities against both conventional and asymmetric threats, favoring systems with proven operational records.

Export Credit and Financing Structures

Hanwha’s export success partly stems from flexible financing arrangements unavailable from some Western competitors.

South Korean government export credit agencies provide favorable terms for approved defense exports, enabling customer nations to spread payment across delivery schedules.

Poland’s massive defense procurements utilize Korean government-backed financing, reducing immediate fiscal impact.

This approach mirrors historical defense export models from other nations but with greater flexibility regarding down payments and interest rates.

Technology Transfer Economics

Local production arrangements, while reducing per-unit profit margins, generate long-term revenue streams from technology licensing, component supply, and sustainment support.

Poland’s Chunmoo rocket factory will source key components from Hanwha Korea, creating export revenues beyond the initial launcher sales.

Australian Redback production requires ongoing supply of specialized subsystems manufactured in Korea, ensuring decades of component exports.

Technology transfer fees and royalty payments provide recurring revenue even after local production achieves full operational capability.

Key Risks and Mitigation Scenarios

Risk Category | Probability | Potential Impact | Mitigation Strategies |

|---|---|---|---|

Geopolitical Export Restrictions | Moderate | High revenue disruption if major customers face sanctions or political barriers | Diversify customer base across regions; establish local production to reduce export dependencies |

Technology Development Delays | Moderate | Schedule slips on indigenous engine could impact credibility | Maintain licensed production relationships as fallback; modular development approach allows partial capability fielding |

Supply Chain Disruptions | Moderate-High | Critical component shortages affect production schedules | Dual-source key components; maintain strategic inventory buffers; vertical integration of critical subsystems |

Competitor Counter-Strategies | High | Western manufacturers adjust pricing or technology transfer policies | Maintain cost advantages through manufacturing efficiency; accelerate indigenous technology to reduce dependency |

Quality/Reliability Issues | Low | Field failures damage reputation in competitive export markets | Rigorous testing protocols; proactive sustainment support; rapid corrective action processes |

Currency Fluctuations | Moderate | Won appreciation reduces export competitiveness | Natural hedges through international production; currency risk management instruments |

Export Control Scenario

Growing U.S.-China strategic competition could trigger more restrictive export controls on dual-use technologies, potentially affecting Hanwha’s access to certain components or manufacturing equipment.

Mitigation requires accelerating indigenous technology development for critical subsystems currently sourced from Western suppliers.

Indigenous Engine Development Risk

Fighter engine development represents one of aerospace’s most technically demanding challenges.

Historical programs demonstrate high failure rates, cost overruns, and schedule delays.

Should the indigenous engine program encounter insurmountable technical barriers, Hanwha maintains relationships with GE Aerospace for continued licensed production, though this outcome would represent a strategic setback.

European Competition Intensification

As European defense industrial base rebuilds, political pressure may emerge to favor domestic suppliers over Asian imports, despite Hanwha’s competitive advantages.

The Germany production facility directly addresses this risk, positioning Hanwha as a European manufacturer rather than Asian importer.

Additional European production sites may become necessary to maintain market access.

Strategic Frameworks: SWOT Analysis

Strengths | Weaknesses |

|---|---|

✓ Only Korean aircraft engine manufacturer | ✗ Technology dependence on Western partners for advanced systems |

✓ Proven export track record (K9, Chunmoo) | ✗ Limited brand recognition compared to established Western primes |

✓ Cost-competitive pricing (20-30% below Western equivalents) | ✗ Smaller R&D budgets than major global competitors |

✓ Willingness to offer technology transfer | ✗ Reliance on Korean government export credit support |

✓ Vertical integration across multiple domains | ✗ Limited presence in Western European and North American markets |

✓ Strong Korean government support | ✗ Perception challenges regarding Asian defense products |

✓ Rapid development and production cycles |

Opportunities | Threats |

|---|---|

⊕ European defense spending increases | ⊖ Technology export restrictions tightening |

⊕ Indo-Pacific security environment drives regional demand | ⊖ Western competitors adopting aggressive pricing strategies |

⊕ Commercial space launch market growth | ⊖ Quality concerns if production scales too rapidly |

⊕ Autonomous systems market emergence | ⊖ Currency appreciation reducing export competitiveness |

⊕ Middle East diversification from traditional suppliers | ⊖ Geopolitical instability disrupting customer procurement plans |

⊕ NATO interoperability requirements favor modern systems | ⊖ Changes in Korean government export policies |

SWOT assessment reflects positioning as of January 2026

Porter’s Five Forces Analysis

Force | Intensity | Assessment |

|---|---|---|

Competitive Rivalry | High | Intense competition from established Western primes and emerging Asian manufacturers; differentiation through pricing and technology transfer |

Threat of New Entrants | Low | Extremely high barriers to entry in aerospace/defense: capital requirements, technical expertise, regulatory approvals, established customer relationships |

Bargaining Power of Suppliers | Moderate | Dependence on Western technology providers for some critical components; vertical integration reduces supplier power in many subsystems |

Bargaining Power of Buyers | High | Government customers wield significant leverage; however, limited alternatives for certain capabilities and financing arrangements reduce buyer power |

Threat of Substitutes | Low-Moderate | Limited substitutes for advanced weapon systems; however, customers may defer procurement or select alternative system types during budget constraints |

Analysis indicates moderately favorable industry structure with primary competitive challenges from established players rather than structural industry forces

The defense aerospace sector’s high barriers to entry protect Hanwha from new competitors, while its growing scale and capabilities improve positioning against incumbent Western manufacturers.

Buyer power remains the most significant structural challenge, though Hanwha’s competitive pricing and financing flexibility partially offset government customer leverage.

PESTEL Analysis Framework

Factor | Impact | Key Considerations |

|---|---|---|

Political | High Positive | ✓ Korean government strategic support for defense exports |

Economic | Moderate Positive | ✓ Strong global defense spending growth |

Social | Low | ✓ Growing acceptance of Asian defense products |

Technological | High Positive | ✓ Successful indigenous development programs |

Environmental | Moderate | ✓ Electric propulsion systems align with emission reduction goals |

Legal | Moderate | ✓ Technology transfer agreements create partnerships |

PESTEL assessment indicates predominantly favorable external environment with political and technological factors providing strongest tailwinds

The convergence of political security concerns, economic defense spending increases, and technological maturation creates an exceptionally favorable environment for Hanwha Aerospace through at least 2030.

Implications for Key Stakeholders

For Defense Procurement Officials

✓ Evaluate Hanwha systems against Western alternatives considering total lifecycle costs,

not just acquisition price

✓ Technology transfer provisions can build domestic industrial capabilities while meeting

immediate operational requirements

✓ Korean export credit financing may enable larger procurements than budget constraints

otherwise allow

⚠ Assess long-term sustainment arrangements and component supply chain resilience

⚠ Consider interoperability requirements with existing allied force structures

For Aerospace Industry Competitors

✓ Monitor Hanwha's pricing strategies in competitive pursuits; may require business model

adjustments to maintain market share

✓ Explore partnership opportunities in complementary capabilities rather than direct

competition

✓ Technology transfer restrictions may provide competitive advantages in certain markets

⚠ Underestimating Hanwha's technical capabilities and development speed represents

strategic risk

For Aviation Industry Suppliers

✓ Hanwha's expanding civil aviation business creates supply chain opportunities as

production volumes increase

✓ Korean government support for aerospace sector may enable large capital investments

in production capacity

⚠ Vertical integration strategy may reduce external supply requirements over time

⚠ Export control compliance essential for companies supplying dual-use technologies

For Aerospace Engineers and Workforce

✓ Hanwha's growth trajectory creates expanding employment opportunities in advanced

aerospace engineering

✓ Indigenous development programs offer participation in cutting-edge technology programs

✓ International expansion creates overseas career opportunities

⚠ Rapid growth may strain organizational capabilities and talent development programs

My Final Thoughts

Hanwha Aerospace has executed a remarkable transformation from a regional defense supplier into a global aerospace competitor, challenging established Western manufacturers across multiple domains.

The company’s 2025 financial performance validates its strategic approach combining cost competitiveness, technology partnerships, and aggressive international expansion.

The convergence of several factors positions Hanwha for sustained growth through 2030 and beyond.

European rearmament, driven by security concerns, creates multi-year procurement pipelines for proven systems like K9 and Chunmoo.

The transition from licensed production to indigenous development in fighter engines and space launch vehicles establishes technological foundations for long-term competitiveness.

Successful execution of the Australian Redback program could unlock additional Pacific region opportunities.

However, significant execution risks accompany this ambitious growth trajectory.

The indigenous fighter engine program represents a technical challenge that has defeated other nations with substantial aerospace industries.

Maintaining quality and delivery performance while scaling production across multiple programs simultaneously will test organizational capabilities.

Currency fluctuations and potential export control restrictions could disrupt carefully constructed international strategies.

For aerospace industry stakeholders, Hanwha’s rise signals a fundamental shift in global defense market dynamics.

The era of Western near-monopoly in advanced weapon systems is ending, replaced by a more competitive environment where capable Asian manufacturers offer credible alternatives at attractive pricing.

This transformation will force incumbent companies to reconsider business models, pricing structures, and technology-sharing policies developed during periods of limited competition.

The coming decade will reveal whether Hanwha can sustain its momentum and complete the transition to fully indigenous advanced aerospace capabilities, or whether technological barriers and market dynamics constrain its ambitions.

Early indicators through 2026 suggest the former outcome appears more probable than skeptics initially assessed.

Company and Other Primary Sources

Official Company Resources:

Financial Reports and Earnings:

Recent Press Releases and Announcements:

News Coverage: