Executive Summary

MTU Aero Engines posted €6.3 billion adjusted revenue in the first nine months of 2025, representing 19% growth year-over-year, with commercial maintenance and engine businesses each growing 20%

The company achieved adjusted EBIT of €995 million through September 2025, up 34%, with margins expanding from 14.0% to 15.9%

GTF Advantage engine certification completed in 2025, with final assembly and deliveries expected to commence by mid-2026

$120 million Fort Worth expansion announced to support LEAP and GEnx engine MRO capabilities, creating 1,200 new jobs through 2050

Also Read:

Table of Contents

Introduction

Germany’s MTU Aero Engines AG delivered record financial results in 2025 and continues its trajectory toward becoming a billion-euro profit powerhouse.

As the aviation industry rebounds from pandemic disruptions and faces new technological challenges, MTU’s dual strategy combining Original Equipment Manufacturing (OEM) with comprehensive Maintenance, Repair, and Overhaul (MRO) services has proven remarkably resilient.

Company Profile

MTU Aero Engines AG stands as Germany’s leading engine manufacturer and ranks among the top 15 global aero engine suppliers. Headquartered in Munich, the company coordinates a worldwide network of subsidiaries and development activities.

The company operates through three core business pillars.

Business Structure:

├── Commercial OEM Business

│ ├── Commercial Series Production

│ └── Spare Parts Business

├── Military Engine Business

│ └── Defense Programs

└── Commercial Maintenance (MRO)

├── Engine Overhaul

├── Leasing & Asset Management

└── Component Repair

As of September 2025, MTU employed 13,444 people globally, representing 4% growth from year-end 2024. The company maintains a robust order backlog of €24.1 billion, primarily driven by the Pratt & Whitney GTF engine family and V2500 programs.

MTU components power one-third of the world’s commercial aircraft. The company participates as a risk and revenue-sharing partner in major engine programs rather than developing complete engines independently.

Revenue Performance and Growth Drivers

MTU’s 2024 financial performance exceeded expectations across all business segments.

The company achieved €7.5 billion in adjusted revenue for fiscal 2024, marking the upper end of its €7.3-€7.5 billion guidance range. More impressively, MTU posted adjusted EBIT of €1,050 million, reaching the billion-euro profit milestone one year ahead of its original plan.

LTM Revenue Breakdown

Through the first nine months of 2025, MTU’s revenue composition demonstrated balanced growth:

Business Segment | 9M 2025 Revenue | 9M 2024 Revenue | Growth Rate |

|---|---|---|---|

Commercial Engine Business | €1.6 billion | €1.4 billion | +20% |

Commercial Maintenance | €4.3 billion | €3.6 billion | +20% |

Military Engine Business | €418 million | €426 million | -2% |

Total Adjusted Revenue | €6.3 billion | €5.3 billion | +19% |

The commercial maintenance business accounted for the largest proportion of revenue at 68% of total sales. Geared Turbofan MRO represented approximately 40% of commercial maintenance revenue in the third quarter of 2025, a proportion the company expects to continue.

Primary Growth Catalysts

Several factors drove MTU’s exceptional revenue performance through 2025.

Commercial series business benefited from high-margin spare and lease engines, though this mix began shifting in quarterly comparisons during 2025. The Pratt & Whitney GTF engine family, GEnx, and V2500 programs served as primary revenue generators.

The spare parts business saw percentage growth in the low teens on a U.S. dollar basis through September 2025. The Geared Turbofan, V2500 for the classic A320 family, and mature widebody engines contributed significantly to spare parts revenue expansion.

CFO Katja Garcia Vila noted during the Q3 2025 earnings call that “Geared Turbofan shop visits increased in the third quarter, as did their material intensity.”

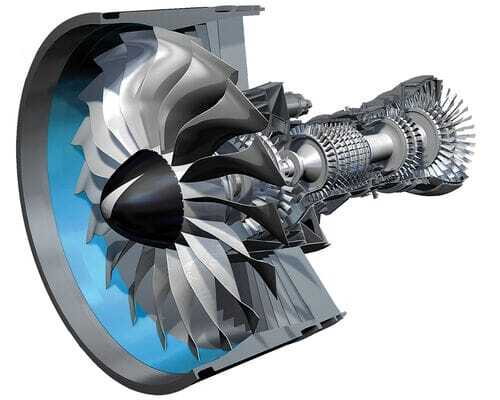

Image source: mtu.de

Key Product Lines and Engine Programs

MTU’s product portfolio spans commercial and military aviation with participation in over 30 engine types worldwide.

Commercial Engine Programs

The Pratt & Whitney GTF (Geared Turbofan) engine family represents MTU’s flagship commercial program. The PW1100G-JM powers the Airbus A320neo family, while variants serve the A220 and Embraer E2 jets.

MTU holds significant workshare in the GTF program, developing and manufacturing the high-speed low-pressure turbine, components for the high-pressure compressor, and various stages of the low-pressure turbine.

The V2500 engine, developed through the International Aero Engines (IAE) consortium, powers classic A320 family aircraft. MTU maintains a 16% program share and manufactures the high-pressure turbine.

For widebody aircraft, MTU participates in several major programs. The company holds a 22.5% stake in the GP7000 engine powering the Airbus A380, making it the largest partner after GE and Pratt & Whitney.

MTU’s involvement in the GEnx program for the Boeing 787 and 747-8 includes responsibility for the high-pressure turbine. The GE90 engine for the Boeing 777 incorporates MTU-manufactured high-pressure turbine components.

Military Engine Portfolio

The EJ200 engine for the Eurofighter Typhoon constitutes MTU’s primary military revenue stream. Providing 20,000 pounds of thrust, the EJ200 ranks among the most advanced fighter engines in its class.

MTU serves as a 33% partner in the Eurojet consortium alongside Rolls-Royce, ITP Aero, and Avio Aero. The company develops and produces the low-pressure turbine and is responsible for final assembly for German engines.

Recent contract awards demonstrate continued momentum for the EJ200 program. In October 2025, the Eurojet consortium signed a contract with NATO’s Eurofighter & Tornado Management Agency (NETMA) to provide 52 new EJ200 engines for the German Air Force.

Spain’s Air Force also ordered 59 EJ200 engines in early 2025, with deliveries scheduled to commence in 2026 to support fleet expansion from 70 to 95 aircraft.

Future Military Programs

MTU holds a 33% stake in the EUMET joint venture with Safran Aircraft Engines, established to develop the New Generation Fighter Engine (NGFE) for Europe’s Future Combat Air System (FCAS).

In June 2025, MTU partnered with Safran Helicopter Engines and Avio Aero to develop engines for Europe’s next generation of military helicopters, strengthening European defense technology sovereignty.

GTF Advantage Certification and Market Entry

The GTF Advantage engine achieved significant regulatory milestones in 2025.

Pratt & Whitney’s GTF Advantage received U.S. Federal Aviation Administration (FAA) type certification for the Airbus A320neo family in February 2025. The European Union Aviation Safety Agency (EASA) validated the certification in October 2025.

These approvals cleared the path for commercial entry into service in 2026.

Performance Improvements

The GTF Advantage delivers substantial performance enhancements compared to standard GTF engines.

The upgraded powerplant provides 4-8% more takeoff thrust, enabling higher payload capacity and extended range. This additional capability unlocks new destination possibilities for airlines operating A320neo family aircraft.

MTU CEO Dr. Johannes Bussmann stated in October 2025 that the company expects to “begin final assembly and deliveries of the new GTF Advantage engines by mid-2026.”

Technical Enhancements

During GTF Advantage development, MTU supported its partners by utilizing fleet experience and applying advanced design and manufacturing capabilities.

The engine incorporates technological improvements to the high-pressure compressor, combustor, and high-pressure turbine. These modifications contribute to improved fuel efficiency and operational performance.

Commercial Maintenance Business Expansion

MTU’s MRO operations represent a critical pillar of the company’s business model.

With approximately 6,000 employees across a global network, MTU Maintenance specializes in customized solutions for commercial and military engines plus industrial gas turbines.

Fort Worth Strategic Expansion

MTU announced a landmark expansion in June 2025 that will transform its North American MRO footprint.

The company signed a 30-year lease with the City of Fort Worth to significantly expand operations at Perot Field Fort Worth Alliance Airport. As part of its long-term investment strategy through 2050, MTU committed $120 million to modernize and upgrade its 43,000-square-meter facility.

The expansion will create approximately 1,200 new jobs. This represents one of the largest aviation industry investments in the Dallas-Fort Worth region in recent years.

LEAP Engine MRO Certification

In April 2025, CFM International designated MTU Maintenance Dallas as a LEAP Premier MRO shop.

This certification enables MTU to perform maintenance, repair, and overhaul services for CFM LEAP engines, which power the Airbus A320neo family (as the LEAP-1A) and Boeing 737 MAX (as the LEAP-1B).

MTU became the sixth exclusive premier MRO service provider worldwide for LEAP engines. The Fort Worth facility worked systematically to meet all requirements for LEAP engine inductions, with support from MTU’s global network.

GEnx MRO Agreement

GE Aerospace and MTU Maintenance signed a new long-term agreement in April 2025 for GEnx engine maintenance services.

The expanded Fort Worth facility will service GEnx engines that power the Boeing 787 Dreamliner and 747-8 aircraft. This addition complements MTU’s existing widebody engine MRO capabilities.

Competitive Positioning and Market Dynamics

MTU operates within a concentrated global aero engine market dominated by a few major players.

Primary Competitors

The commercial aircraft engine industry features an oligopolistic structure with four primary manufacturers controlling approximately 99% of the market.

General Electric (GE Aerospace) stands as the world’s largest aircraft engine manufacturer. GE produces the CF6, GE90, and GEnx for commercial widebody aircraft, and participates in CFM International (50/50 with Safran) producing the CFM56 and LEAP engine families.

Pratt & Whitney (RTX Corporation) serves as MTU’s most significant partner and occasional competitor. Pratt & Whitney leads the GTF engine family development and maintains strong positions in both commercial and military markets.

Rolls-Royce Holdings plc competes directly with MTU across civil and military engine programs. The British manufacturer supplies the Trent engine family for widebody aircraft and the Pearl engine for business jets.

Safran Aircraft Engines (through CFM International with GE) produces the world’s best-selling commercial engine family. Safran also partners with MTU on military programs including the NGFE for FCAS.

MTU’s Competitive Advantages

MTU’s business model differs fundamentally from full-spectrum engine manufacturers.

The company operates as a risk-and-revenue-sharing partner rather than prime contractor. This approach provides several strategic benefits.

MTU participates in multiple competing engine programs simultaneously. For example, the company holds stakes in both the Pratt & Whitney GTF and CFM LEAP programs for narrowbody aircraft, ensuring revenue streams regardless of which manufacturer wins individual orders.

The company’s deep technical expertise in high-pressure and low-pressure turbine manufacturing has made it an indispensable partner for major engine OEMs. MTU’s turbine components operate in the most demanding sections of jet engines, demonstrating the company’s metallurgical and engineering capabilities.

MTU’s integrated OEM and MRO business model creates synergies unavailable to pure-play manufacturers or maintenance providers. Knowledge gained from MRO operations informs design improvements, while OEM expertise enhances maintenance efficiency.

MTU’s market positioning reflects its partnership-based strategy rather than direct competition.

In the narrowbody segment, MTU benefits from the strong performance of both GTF and V2500 engines. The A320neo family (powered by either GTF or LEAP engines) dominates the single-aisle market alongside the 737 MAX family.

The widebody market presents more complexity. MTU participates in the GE90 for the 777, GEnx for the 787 and 747-8, and GP7000 for the A380. This diversification across multiple programs provides stability despite varying platform production rates.

Sustainable Aviation Technologies

MTU has committed substantial resources to developing propulsion systems for zero-emission flight.

Flying Fuel Cell Program

MTU’s Flying Fuel Cell (FFC) represents the company’s flagship hydrogen-electric propulsion project.

In June 2025, Airbus and MTU signed a Memorandum of Understanding to progress together on hydrogen fuel cell propulsion technology.

The FFC system converts liquid hydrogen into electricity through fuel cell stacks. MTU is developing a complete liquid hydrogen aircraft fuel system including tanks, sensors, heat exchangers, valves, and safety systems.

Important technical milestones achieved by mid-2025 included finalizing the FFC design and commencing fuel cell stack production. The electric motor underwent testing and the test cell infrastructure was completed.

Hydrogen Testing Success

MTU successfully completed multi-week testing of its liquid hydrogen fuel system in late 2024. This validation represented a critical step toward demonstrating the viability of hydrogen-electric propulsion for commercial aviation.

The FFC technology targets initial applications in short-haul routes and regional air traffic. MTU anticipates completion of development by 2035, with the technology potentially entering service on regional aircraft first.

Development Roadmap

Airbus and MTU outlined a three-step roadmap for hydrogen fuel cell engine development announced at the 2025 Paris Air Show:

Phase 1: Ground Demonstrator (2026-2028)

├── Integrated system testing

└── Performance validation

Phase 2: Flight Demonstrator (2028-2032)

├── Airborne system integration

└── Operational testing

Phase 3: Certification & Entry Into Service (2032-2035)

├── Regulatory approval

└── Commercial deployment

The partnership positions both companies to lead Europe’s transition toward sustainable aviation propulsion technologies.

Recent Strategic Developments

MTU executed several significant strategic initiatives through 2025 and early 2026.

Convertible Bond Offering

In January 2026, MTU launched a dual financial strategy comprising a new convertible bond offering and a solicitation to repurchase existing bonds.

The company successfully placed €600 million in new senior, unsecured convertible bonds maturing in July 2033. Simultaneously, MTU solicited offers from investors to sell up to €500 million of outstanding convertible bonds due in 2027.

This refinancing strategy extends MTU’s debt maturity profile and provides financial flexibility for growth investments. The new bonds carry favorable terms reflecting strong investor confidence in MTU’s long-term prospects.

Leadership Transition

MTU implemented a leadership transition in its commercial engine business effective January 2026. The appointments support the company’s strategic evolution and prepare for continued growth in commercial aviation markets.

Supply Chain Stabilization

MTU made substantial progress addressing supply chain challenges through 2025. CEO Johannes Bussmann stated in June 2025 that “we are optimizing our supply chain and investing in our sites and our people.”

While supply chain volatility persists across the aerospace industry, MTU noted improvements in recent quarters. The company implemented measures to secure critical materials and components for both OEM and MRO operations.

Financial and Commercial Outlook

MTU’s financial trajectory through 2025 exceeded initial guidance, prompting upward revisions.

2025 Performance

For fiscal 2025, MTU raised its guidance in October to reflect stronger-than-expected results through the first nine months.

Metric | Updated 2025 Guidance | Previous Guidance |

|---|---|---|

Revenue | €8.6-€8.8 billion | €8.3-€8.5 billion |

Adjusted EBIT Growth | Mid-twenties percentage | Low to mid-twenties percentage |

Free Cash Flow | €350-€400 million | €300-€350 million |

Effective USD/EUR Rate | 1.13 | 1.10 |

CFO Katja Garcia Vila commented: “We anticipate a mid-twenties percentage increase in adjusted EBIT for 2025, hitting the upper end of our previous guidance range.”

All business areas contributed to revenue growth. Commercial maintenance showed the strongest gains with percentage growth in organic revenue reaching the mid to high teens. Commercial series business achieved mid-teens percentage organic revenue growth, while spare parts business posted low to mid-teens growth.

2030 Strategic Targets

In June 2025, MTU provided an initial outlook for 2030, establishing long-term financial objectives.

The company aims to capitalize on favorable commercial aviation market dynamics while investing in future technologies. Specific 2030 targets remain subject to ongoing strategic reviews, but MTU expressed confidence in sustained revenue and earnings growth trajectories.

GTF Inspection Program Impact

The ongoing GTF inspection program continues to influence MTU’s financial performance. The expanded inspection requirements result in 600-700 additional shop visits for PW1100G-JM engines over the coming years.

For 2026, MTU expects an impact of approximately €200 million related to customer compensation payments associated with the inspection program. Despite this near-term headwind, the company maintains positive medium-term guidance based on strong underlying demand.

Margin Performance

MTU achieved impressive margin expansion through 2025. Adjusted EBIT margin increased from 14.0% in the first nine months of 2024 to 15.9% in the same period of 2025.

The OEM business delivered particularly strong margin performance. Adjusted EBIT margin in OEM operations rose from 24.7% to 31.1%, driven by favorable product mix and spare parts growth.

Commercial maintenance held margins relatively steady at 8.3% (compared to 8.4% in 2024) despite costs associated with the Fort Worth facility ramp-up and higher proportion of Geared Turbofan MRO work.

Key Operational and Strategic Risks

MTU faces multiple risk categories that could impact future performance.

GTF Engine Durability Issues (Probability: Moderate to High)

The Pratt & Whitney GTF engine family has experienced durability issues requiring accelerated inspections and component replacements.

Primary Concern: Powdered metal contamination in high-pressure turbine disks manufactured by a third-party supplier necessitated widespread engine inspections.

Impact Scenarios:

Base Case (Moderate Impact): Inspection program proceeds as currently planned with 600-700 additional shop visits. MTU absorbs approximately €200 million in customer compensation annually through 2026-2027.

Adverse Case (High Impact): Additional undiscovered quality issues emerge, requiring more extensive inspections or component replacements. Industry confidence in GTF platform erodes, leading to order cancellations or platform switches.

Mitigation Actions: Pratt & Whitney and MTU have implemented enhanced quality control processes. The GTF Advantage incorporates design improvements addressing known durability concerns.

Supply Chain Disruptions (Probability: Moderate)

Global aerospace supply chains continue experiencing strain from post-pandemic recovery, skilled labor shortages, and raw material availability constraints.

Primary Concern: MTU’s production schedules depend on hundreds of suppliers providing castings, forgings, and specialized components on time and to specification.

Impact Scenarios:

Base Case (Moderate Impact): Periodic delays in component delivery require production schedule adjustments. Some customers experience delivery postponements of 2-4 months.

Adverse Case (High Impact): Critical supplier bankruptcies or sustained delivery failures force MTU to qualify alternative sources, causing 6-12 month production delays and revenue recognition shifts.

Mitigation Actions: MTU is implementing supply chain optimization initiatives and has invested in securing critical materials. The company maintains closer collaboration with key suppliers to identify and address bottlenecks early.

Commercial Aviation Demand Volatility (Probability: Low to Moderate)

Commercial aviation markets remain subject to cyclical demand patterns and external shocks.

Primary Concern: Economic recessions, pandemic resurgences, geopolitical conflicts, or fuel price spikes could suppress air travel demand and reduce airline profitability.

Impact Scenarios:

Base Case (Low Impact): Regional demand variations and modest cyclical fluctuations occur but global trend remains positive. MTU’s diversified program portfolio provides stability.

Adverse Case (Moderate Impact): Global economic downturn triggers 15-25% reduction in air travel demand for 18-24 months. Airlines defer aircraft deliveries and reduce maintenance spending, impacting both OEM and MRO revenue streams.

Mitigation Actions: MTU’s multi-program participation and geographic diversification provide natural hedging. The company maintains financial flexibility to navigate cyclical downturns.

Technological Transition Risks (Probability: Moderate)

The aviation industry’s transition toward sustainable propulsion creates uncertainty around technology pathways and timing.

Primary Concern: Investments in hydrogen-electric propulsion, sustainable aviation fuels, or other emerging technologies may not yield commercial returns if alternative solutions prevail or timelines extend beyond current expectations.

Impact Scenarios:

Base Case (Moderate Impact): Hydrogen and electric propulsion develop as anticipated but require higher R&D spending than planned. Traditional turbine engines remain dominant through 2040.

Adverse Case (High Impact): Regulatory mandates accelerate zero-emission requirements before hydrogen-electric technology matures commercially. MTU faces pressure to write down traditional engine investments while simultaneously funding alternative propulsion development.

Mitigation Actions: MTU pursues multiple technology pathways including evolutionary turbine improvements, sustainable aviation fuel compatibility, and revolutionary hydrogen-electric propulsion. Research partnerships with Airbus and others distribute development risks and costs.

Military Program Concentration (Probability: Low to Moderate)

MTU’s military business relies heavily on the EJ200 Eurofighter program for revenue.

Primary Concern: Budget pressures, program cancellations, or platform obsolescence could reduce military engine demand.

Impact Scenarios:

Base Case (Low Impact): Eurofighter orders continue from existing and new customers. New Generation Fighter Engine (NGFE) development proceeds as planned, providing long-term military revenue visibility.

Adverse Case (Moderate Impact): European defense budget cuts lead to reduced Eurofighter orders. FCAS program experiences delays or cancellations, leaving MTU without next-generation military programs.

Mitigation Actions: MTU diversified into military rotorcraft propulsion through partnerships with Safran and Avio Aero. The company maintains participation in U.S. fighter programs (F110, F414) for additional revenue streams.

Strategic Analysis Frameworks

SWOT Analysis

Strengths | Weaknesses |

|---|---|

• Strong partnerships with all major engine OEMs (GE, P&W, Rolls-Royce, Safran) | • Limited control as junior partner in most programs |

Opportunities | Threats |

• Commercial aviation recovery driving strong aftermarket demand | • Extended GTF inspection program requiring significant customer compensation |

Porter’s Five Forces Analysis

Force | Assessment | Rationale |

|---|---|---|

Competitive Rivalry | Moderate | Oligopolistic market structure with 4 major players controlling 99% of market. Competition occurs at OEM level (GE, P&W, Rolls-Royce, Safran) while MTU participates as partner across multiple programs. High switching costs and long development cycles reduce direct competition intensity. |

Threat of New Entrants | Very Low | Extremely high barriers to entry including multi-billion dollar development costs, decades-long certification processes, and established customer relationships. Chinese engine manufacturers represent only long-term potential entrants but lag significantly in technology and reliability. |

Bargaining Power of Suppliers | Moderate to High | Specialized aerospace suppliers possess significant power due to limited alternatives for critical components (titanium castings, superalloy forgings). However, MTU’s scale and long-term contracts provide some countervailing leverage. Supply chain concentration creates vulnerability. |

Bargaining Power of Buyers | Moderate | Airlines and aircraft OEMs possess substantial buying power due to large order volumes and ability to switch between competing engine options on new aircraft. However, aftermarket lock-in and certified parts requirements reduce buyer power post-purchase. Military customers have limited alternatives. |

Threat of Substitutes | Low to Moderate | No near-term substitutes for turbine engines in commercial aviation. Long-term threats include hydrogen-electric propulsion and battery-electric systems for regional aircraft. Sustainable aviation fuels reduce substitution threat by enabling continued turbine usage with lower emissions. |

PESTEL Analysis

Factor | Key Considerations | Impact on MTU |

|---|---|---|

Political | • European defense spending increases supporting military programs | Positive: Increased defense budgets benefit EJ200 and NGFE programs. Government R&D co-funding reduces MTU’s hydrogen-electric development costs. |

Economic | • Commercial aviation recovery post-pandemic | Mixed: Strong aviation recovery drives revenue but inflation increases costs. Dollar strength benefits revenues but creates competitive pricing pressure. |

Social | • Growing environmental consciousness affecting travel patterns | Mixed: “Flight shaming” trends in Europe create pressure for zero-emission technologies. Workforce shortages constrain production ramp-up but support wage moderation through employee retention priorities. |

Technological | • Geared turbofan technology advancement | Positive: MTU’s technology investments position company for next-generation propulsion leadership. Digital maintenance capabilities enhance MRO competitiveness and margins. |

Environmental | • ICAO Carbon Offsetting and Reduction Scheme (CORSIA) | Mixed: Environmental regulations drive demand for more efficient engines (benefiting GTF) but require substantial R&D investments. Long-term zero-emission mandates could obsolete current turbine technology prematurely. |

Legal | • Aviation safety regulations and certification requirements | Neutral to Negative: Stringent regulations increase development costs and timelines. GTF quality issues expose MTU to potential liability claims. Export controls limit military business geographic expansion. |

Stakeholder Implications

Different stakeholder groups face distinct implications from MTU’s strategic position and operational performance.

Airlines and Aircraft Operators

Key Implications:

GTF-powered aircraft offer 15-20% lower fuel consumption compared to previous generation engines, reducing operating costs

Ongoing GTF inspection program causes aircraft availability challenges requiring fleet planning adjustments

GTF Advantage availability from mid-2026 provides performance improvements and operational flexibility for A320neo operators

Actionable Considerations:

Diversify engine selections across new aircraft orders to avoid single-engine-type fleet concentration

Negotiate comprehensive maintenance agreements with MTU Maintenance for GTF-powered fleets

Monitor sustainable aviation fuel compatibility for long-term fleet planning

Aircraft Manufacturers (Airbus, Boeing, Embraer)

Key Implications:

MTU’s production capacity and supply chain health directly affects aircraft delivery schedules

GTF Advantage certification enables Airbus to offer enhanced A320neo variants competing more effectively against 737 MAX

MTU’s hydrogen-electric propulsion development creates potential zero-emission aircraft options for 2035+ timeframe

Actionable Considerations:

Maintain close coordination with MTU and Pratt & Whitney on GTF production ramp schedules

Incorporate MTU’s Fort Worth MRO expansion into North American aftermarket support strategies

Engage MTU early in next-generation aircraft propulsion requirements definition

Defense Ministries and Armed Forces

Key Implications:

EJ200 engine remains cornerstone of European fighter capabilities through 2040+

NGFE development for Future Combat Air System ensures European engine technology sovereignty

MTU’s military helicopter propulsion partnerships strengthen European defense industrial base

Actionable Considerations:

Plan Eurofighter sustainment budgets for continued EJ200 support through mid-century

Allocate FCAS development funding to maintain NGFE program schedules

Leverage MTU’s dual civil-military technology base for cost-effective military engine solutions

MRO Service Providers

Key Implications:

MTU’s Fort Worth expansion intensifies competition for widebody and narrowbody MRO work in North America

LEAP and GEnx certification positions MTU as comprehensive MRO provider competing with GE and Safran shops

GTF inspection program creates near-term capacity constraints across industry, benefiting all qualified providers

Actionable Considerations:

Differentiate service offerings through turnaround time, quality, or specialized capabilities

Consider partnership or acquisition opportunities to achieve scale advantages

Invest in GTF, LEAP, and GEnx capabilities to serve growing installed base

Suppliers and Supply Chain Partners

Key Implications:

MTU’s production ramp requires increased component deliveries with strict quality requirements

Long-term partnership opportunities exist for suppliers demonstrating reliability and innovation

Supply chain optimization initiatives may consolidate supplier base, creating winners and losers

Actionable Considerations:

Invest in capacity expansion and quality systems to meet MTU’s growing requirements

Develop advanced manufacturing capabilities (additive manufacturing, advanced coatings) to enhance value proposition

Maintain financial stability to weather aerospace industry cyclicality

Technology and Research Partners

Key Implications:

MTU’s hydrogen fuel cell program offers collaboration opportunities for fuel system, materials, and integration technologies

Clean Aviation research programs provide co-funding for sustainable propulsion development

Digital twin and predictive maintenance initiatives require data analytics and software partnerships

Actionable Considerations:

Align research roadmaps with MTU’s technology development timelines and priorities

Pursue joint intellectual property arrangements balancing innovation incentives with commercialization rights

Demonstrate technology maturity through ground testing and validation to accelerate adoption

Primary Sources and Company Information

Official MTU Communications:

MTU Q3 2025 Financial Results Press Release (October 23, 2025)

MTU 2024 Annual Report (Published February 2025)

MTU Investor Presentation (September 2025)

MTU 2025 Guidance Update (June 17, 2025)

Recent Developments:

Fort Worth Expansion Announcement (June 2025)

GTF Advantage Certification (February 27, 2025)

LEAP MRO Certification (April 8, 2025)

Airbus Hydrogen Partnership (June 18, 2025)

News Coverage:

Reuters: MTU beats profit estimates (October 23, 2025)

Regulatory Filings:

MTU Convertible Bond Offering Documentation (January 2026)

EASA GTF Advantage Type Certification (October 2025)

FAA GTF Advantage Type Certification (February 2025)

My Final Thoughts

MTU Aero Engines enters 2026 from a position of financial strength and strategic momentum. The company’s €7.5 billion revenue in 2024 and continued growth through 2025 demonstrate the resilience of its dual OEM-MRO business model.

Here are the top three factors that could determine MTU’s trajectory over the next 3-5 years.

First, successfully resolving GTF durability issues and restoring industry confidence remains paramount. The GTF Advantage certification provides a technical solution, but MTU and Pratt & Whitney must demonstrate sustained reliability improvement. Any additional quality problems could permanently damage the platform’s competitive position against CFM’s LEAP family.

Second, MTU’s Fort Worth expansion represents the company’s largest strategic bet in North America. The $120 million investment positions MTU to capture substantial MRO market share in LEAP and GEnx engines. Execution risks include workforce recruitment, quality control during ramp-up, and achieving target productivity levels. Success could establish MTU as the premier independent MRO provider in North America by 2028.

Third, hydrogen-electric propulsion development will define MTU’s long-term competitiveness. While the Flying Fuel Cell program won’t enter commercial service until the mid-2030s at earliest, leadership in zero-emission technology could determine which companies survive the inevitable industry transition away from conventional turbines. MTU’s partnership with Airbus provides validation and resources, but the technology pathway remains uncertain and expensive.

The company’s financial guidance for 2025 (€8.6-€8.8 billion revenue, mid-twenties percentage EBIT growth) appears achievable based on third-quarter momentum. The commercial maintenance business should continue benefiting from high GTF shop visit volumes, while OEM margins remain strong due to favorable spare parts mix.

MTU’s partnership-based business model, once viewed as a limitation compared to full-spectrum manufacturers, now appears prescient. Participating in multiple competing programs provides natural diversification while avoiding the capital intensity of independent engine development.

As long as Pratt & Whitney, GE, Rolls-Royce, and Safran continue developing new engines, MTU will remain an essential partner given its turbine manufacturing expertise.

For aviation industry stakeholders, MTU’s performance serves as a bellwether for commercial aviation health.

The company’s diversified exposure across narrowbody, widebody, and military segments provides comprehensive insight into global aerospace trends.